Update 26/3/23. I won't be buying another SCS system. They are poorly designed, have no free support and have almost no adjustments. Even if support is free you can't change much. They are cheap for a reason. See the update towards the end for the latest damage caused by the system and the remedial action taken.

And now a rant about problems during an install of SCS1 one gate 27/7/22. The system it replaces has always had a dodgy motor and recently it would open and then automatically close; this is probably excessive motor current. However a new motor is around 100€ and a new system 121€. Looks like companies like to support land-fill and new sales.

I installed a 12V pro version around 9 years ago and my main complaint then is pretty much the same now. SCS buy cheap mains transformers. So cheap that the copper loss on them costs you money. Back in 2013 I reported a staggering 9W loss on a 100VA toroid. That is truly impressive as toroids are normally very low loss.

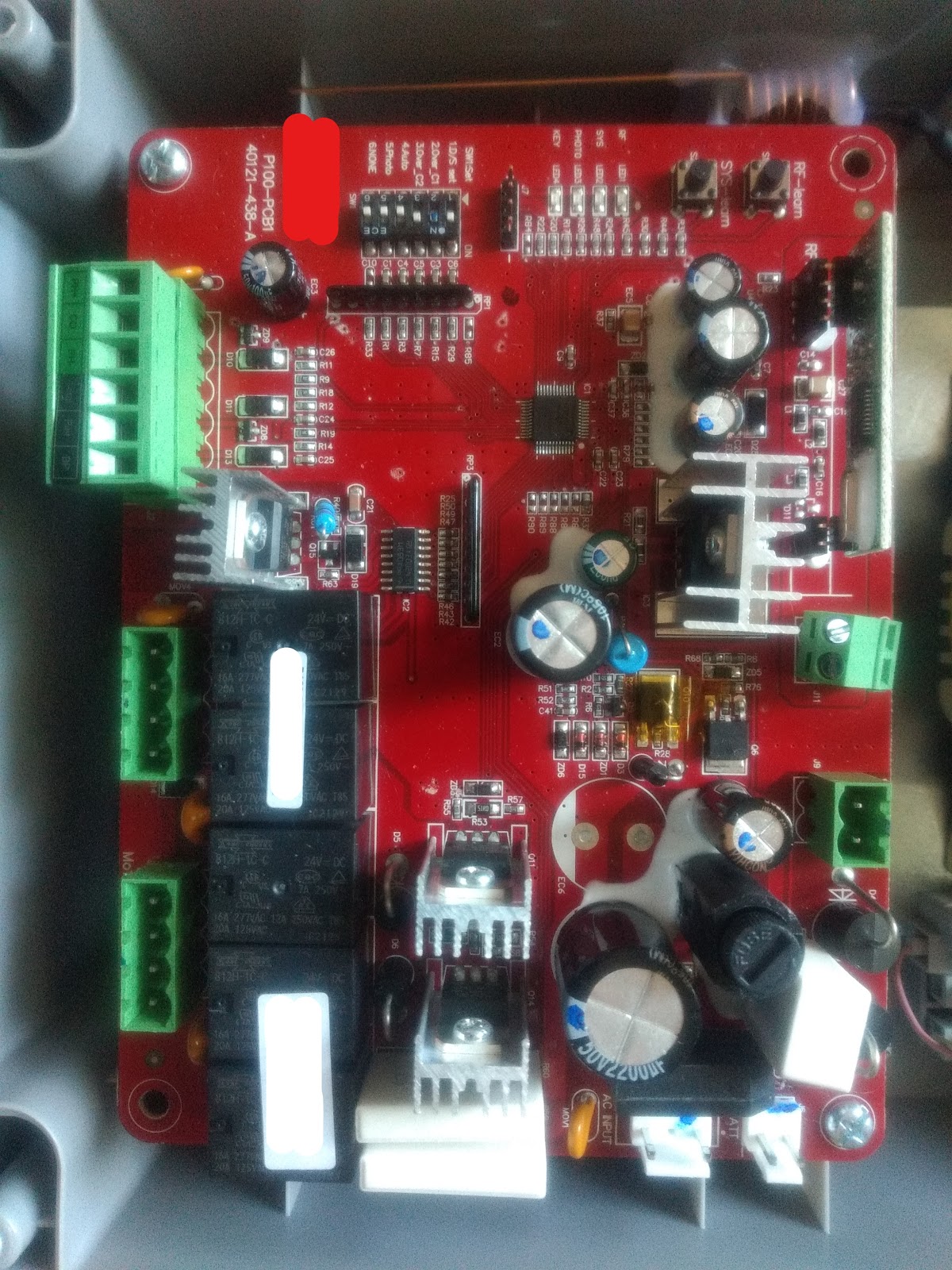

The trafo in the new unit is made by the world renown 'just for you enterprise' and it improves losses slightly, compared to the toroid, with only 7.5W of loss for a 80VA unit. To put this into context at 2013 prices, the waste on the original unit is 9€/year, so 81€ through life. At 2022 prices it's closer to the price I've just paid for the replacement system (121€)

As I reported in 2013, I fitted a small mobile charger to keep the electronics working which uses 1W. This wasn't quite possible with the new system as they've installed a low voltage dropout for the battery. It's set to 24V which is way too high. You'd normally cut off at 1.75/cell = 10.5V, or 21V. However, an old 18V DC wall wart did the trick plugged into the PV connector. Once the gates try to open, a trigger on the flashing beacon turns on the original transformer. So no changes to the pcb, so warranty intact. For info the main trafo puts out 28V, giving a FWB output of nearly 40VDC. When both motors are running this drops to 32VDC.

Incidentally if you do fit a battery, just check how the charger works. I measured 40V at the battery terminals for a 24V battery (no battery), but it's fed through a FET Q6, and there is a voltage feed to the processor, so hopefully they will PWM the supply. I'm not interested in replacing lead every few years for a possible annual use, but YMMV.

Depending on whether you think it's worth the effort, some maths. I have 3 of these poorly designed products. 2 for garage doors and 1 for gates. They would waste around 30€ of leccy per year, or 185kWh. If every home in France wastes the same, that's 3700MWh, or 1 large nuclear plant.

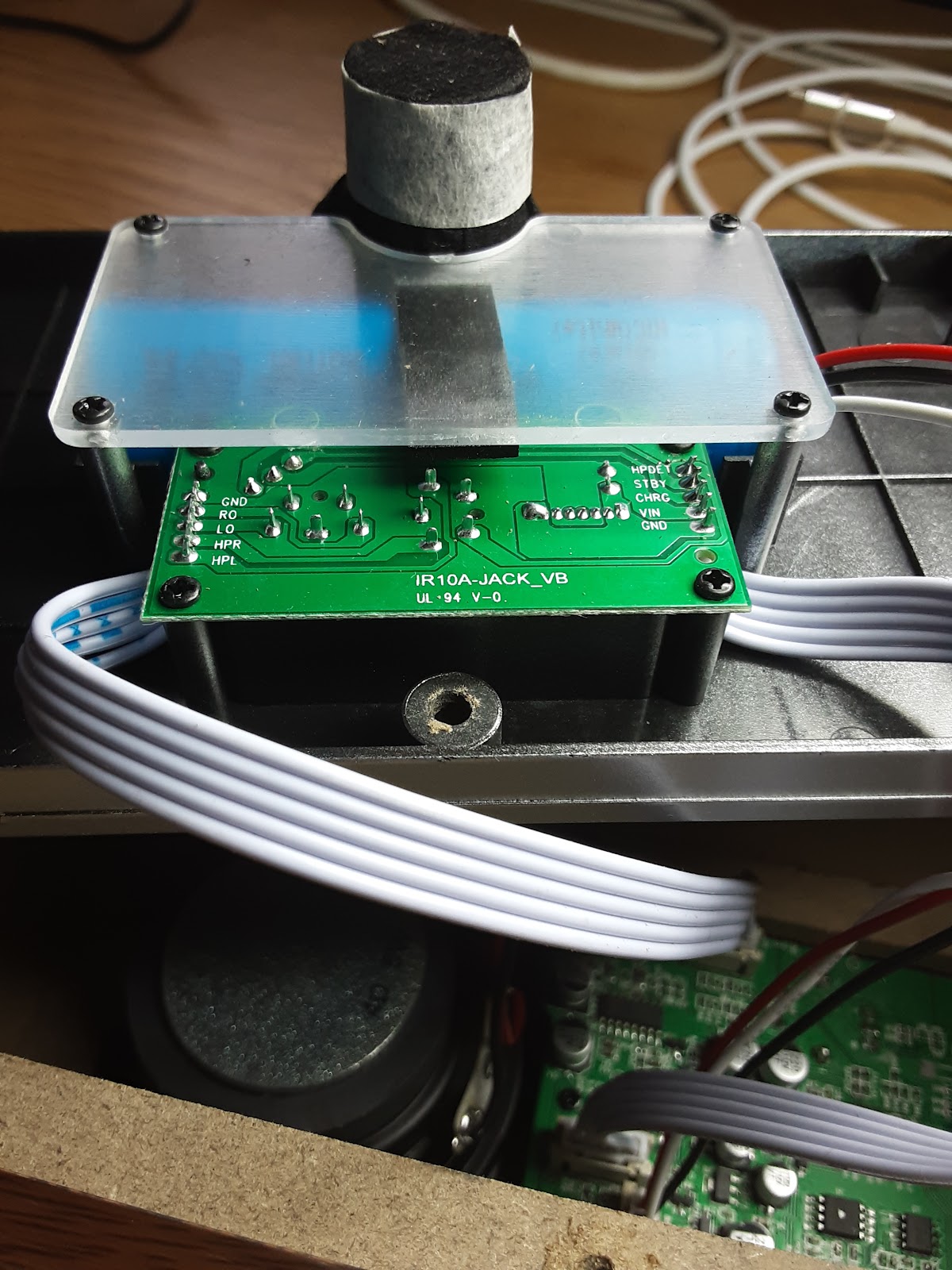

The new system doesn't show gates closed, so I'm using a reed switch and a magnet to easily show this. I've also added a photocell beam which will double up as a door bell if anyone goes through the beam when the gates are open.

The beacon I have (no new one) uses a 12V bulb. I couldn't find another bulb to put in series, so robbed the 96V/76mA led panel out of an old broken light 7W and I run 4 LEDs in series off a constant current (LM317 app note) of 36mA to give a 1.2W/12W equivalent light. Must have at least 30V to light it and it takes 17mA at 34V.

The picture shows the LEDs in a SES base. It turned out the bulb holder was too tall, so I used choc block in the end, with the original diffuser balanced on top of the LEDs

The motors/arms have plastic parts, so we'll see how that works out. The motor is underneath and you can just see the metal worm drive on the left.

I didn't analyse the remotes too much, but they are Keeloq (HCS301) and use rotating codes. SCS have helpfully changed the manufacturer's code, so any remotes from the old system (also HCS301) are now bin fodder. Really well done SCS. Nothing like re-use in your book.

Bent trafo on delivery

The mains fuse block is incorrectly installed and badly stresses the trafo connections when the fuse is inserted/removed. Oddly, the manual has a photo of the correctly oriented installation of the holder, but the manual drawing is incorrect. Go figure.

And why do you suppose that the motors slow down at end of travel, but not when starting, so the motors, gates, mounting, etc are all given a good yank.... I knew I should have just designed my own.

My favourite fuck up by far is the wiring for the internal aerial. Whilst they have done a lovely job (really) of making a good internal one, if you replace it with an external one be really really careful. The screw terminals for the aerial are just behind a heatsink with +14V, so you have every chance of grounding the 14V rail. You will most likely destroy the regulator. Turn off at the mains and open the gates to discharge everything.

26/3/23. A sorry state of affairs. I have outward opening lightweight gates. The outward opening isn't really much different, and this will stress mounts slightly more due to the angles between the various components. However, the poor design of the product exacerbates any issues.

For example, the power supply for the 24V gate motors comes from a simple trafo that gives 32V DC when both are running, and around 36V for one. This means that the motors draw less current (whilst being damaged on over-volts) and the current sensing works less well. You have a choice of 2,3,4 or 5A. If I select 2A it's ok in the summer and wont open in the winter. Easy fixed if they bothered to install a temperature sensor. A 24V supply would help too. But even then, the current sensing is so bad at 2A that it rips the motor fixing out of a concrete pillar. The manual shows plastic rawl plugs. LOL. I used 10cm M10 rod and chemical anchors. Lasted about 2 weeks. I've used exactly the same fixings on a 1.4m satellite dish and that's not moved in some very strong wind.

I've just put a welded steel band around the pillar using 6mm plate, and it's managed to bend that. I can just about bend this steel it in the vice. A really very poorly designed system.

I've managed to prevent this damage at fully open by moving the bracket on the gate to just beyond maximum piston extension, so the gearbox locks itself. However the shutting force is similar, so I'll have to weld some angle iron in place. I guess I'll be reporting gearbox failure in a few weeks.....

The other side is even worse. I'd put a bolt through the pillar to hold the motor bracket in place, but the continual excessive force made the bolt hole oval and a large piece of concrete has been ripped out. The control box was on this concrete but luckily I spotted it in time and thus saved replacing a 30€ plastic box (and land-filling the broken one). I'll make a similar bracket and retaining the through bolt to stop the bending.

I'm actually half hoping that I hit and damage these motors so I can justify chucking them.

The replacement from a decent company that has proper force control and/or end stops will cost 500€+ and will install in a few hours. And I'll never need to look at them again. I know this because I look after another house that has a well designed system, from a company that doesn't sell items ready for landfill. Flawless.

I really really hate shit design. It doesn't take much more effort to produce something good and long lasting. There are plenty of complaints on-line, but companies will never read posts whilst continuing to claim that they have almost no complaints. Been there, had the argument. Why would they go looking for trouble in 'unverified' posts?

The metal bending in the picture above got worse, so I ended up putting a bolt through the band. It's been 3 months and nothing has broken...