And so it begins..

24/1 Cleared a bit more garage, worked out levels and soil pipe. From the internal wall, the slab is highest along the adjoining wall, so had to removed some floor, and trimmed 2; 1 10mm, one 4mm. The floor then sloped and lost 40mm nearest the car door, vs 25mm opposite the internal wall.

25/1 Cut joists, fitted hangers, cut insulation. Extra support under joists nearest internal partitions, and 1 under trimmed joist (-10mm, but calcs still ok) which sits under the washing machine.

26/1/21 Secured base to garage floor, fixed 2 hangers in the wrong place, fitted deck. Filled gap between house and utility (3 hours!) Ran conduit for new supply. W/m mains cut into deck ready for partition.

27/1. Rafters are not parallel to house wall. Put up outside partition rail + some uprights. Wired the earth in. More screws required! Ordered workstops + cabinets.

28/1 finished base of internal skin. Put up 2 boards of external skin. Removed existing sockets off wall and put 3 new on 2 boards. Moved tools and put up a small bench.

29/1 pm doubled up 2 joints on osb. put up ceiling rails + some spans

30/1 corrected ceiling rail on outer skin - 13mm too low. 2 ceiling sheets. Internal PB rails and 1 sheet. Dis board, temp feed + 1 light.

31/1 finshed osb top/bottom rail, ceiling rail, ceiling spans. Cut all metal uprights, but several left unconnected to the ceiling to allow PB to be carried in and twisted easily. Ceiling FG + 2 walls (mistake - should have done this yesterday, but didnt want to get covered in FG) Run out of base rail.

2/1 --

2/2 loft tidy, fit remaining ceiling plasterboard. Ran in most conduits, pulled supply cables. Chased in sockets and fished between.

3/2 move garage light switches temporarily, install outside water pipe. Clean wall, glue plasterboard (all afternoon for 3 sheets - use low expansion foam next time. About 9L of glue per board comes from 15kg + 9L water ie 15kg for 6m2. Too much. Tried 4.5kg + 2L for 2m2 and still too much. Mix up pretty thick)

4/2 install sockets in glued plasterboard, build loo temporarily and set up waste. Screwed down floor + finish floor around waste.

5/2 Cut light holes. Fitted rails for internal skin.

6/2 moved garage light switch from utility to garage with temporary extensions. Added permanent live to garage light and put in a socket. Put door opener back onto original trafo. Framework for lobby and temporary plasterboard. 1 sheet of plasterboard and osb plus insulation. Drilled hole and fed conduit for shed. Final piece of ceiling plasterboard fitted. Removed trailer wheel, tidied and moved all 12mm osb to be fully upright by screwing it to the last sheet. Most had developed a bowed middle. Moved remaining 7 sheets of plasterboard into the utility. Worked out where utility door will go.

7/2 --

8/2 fitted utility door and main door, boxed out frame, light switches.

9/2 Finished utility door. Fitted loo frame/door. Misc bits. Tidy.

10/2 pulled all remaining wiring. Lights in. Looked at window location. pm --

15 working days to date.

11/2 cut & glued plasterboard around arch. Cut frame for window. Cut a sheet of osb3 to finish run to door and wall above bench. Tested quick setting joint filler, about 8 years old and it was fine! Taped and jointed wall side of utility.

12/2 pm stitch drilled for support below lintel. 26mm board, 760 long. Mortered in with fresh cement.

13/2 Fished congealed lighting. Wood for worktop, wood for hooks, fire extinguisher. Finished hook wall (needs insulation) Finished pillar/ reveals. plumbed outside tap. Sealed gaps between slab and floor - removed plot and replaced with wood to allow better draught seal.

14/2 -

15 cut window opening, block hole, render up sides to fill gaps and tidy (red dust everywhere)

16 make sides for window to make thickness to 150mm- oops should have been 163mm. Fit support on window underside. Fit window. Test 11yo bag of Weber render by putting a scratch coat on the top reveal to fill in the large gaps.

17 1/2 day. tidy, fit sill, fit window. Bit of a devil as the frame twists, so catches on opening

18 2 layers of silicone around window inside. Framed and insulated. Worked out where basin will go.

19 pm install loo

20 am plumbing for basin

22.5 days to date

21-

22-

23 dummy install of pan. Seems frame is twisted and can't get pan level. Moved cooker and pulled back 15mm outside tap feed and rerouted it into utility. Added 16mm per to hot. No joins. Fitted manifolds, connected outside tap and loo. Tried drilling a hole through the bricks near the loo with the intention of leaving a threaded rod for future pan retention if plugs fail, but can't reach by about 100mm.

24 1/2 day. Manifolds now live. Leak on soldered joint on outside tap, but now considering moving tap to inside shed. Plumbed basin.

25 changed plugs at top of loo bracket to those provided. Much more solid than 100mm hammer in. Moved outside tap to shed. Glued most of sink waste. Fitted plasterboard around window and installed sink.

26 <1/2 day. Installed window grill, glued soil pipe. Replaced loo top wall plugs.

The bricks have the first web at 40mm, so can use plugs of around 60mm ok. If they have anti rotation tags on the head, file a flat for them. 100mm hammer in dont work. 80 generally OK.

27 test soil pipes. Reinstall loo partition. Install light switch. Chop 10mm off manifold brackets else worktop of 40mm may not fit. Metal for cistern partition. Hole for 32mm waste.

26.5 days

28-

1/3 glued floor joints from top. Screw down lobby to kitchen bit of floor. Cut plasterboard + glued. Finished all partitions and loo openings.

2/3 prep for first joint + joint.

3/3 am 3h. Scrape back ready for top coat. Pm 2h 2nd coat ex corners + 3 corners 4h.

4/3 am scrape back, sand, caulk and size.

5/3 pm paint

6/3 am tile prep, lights

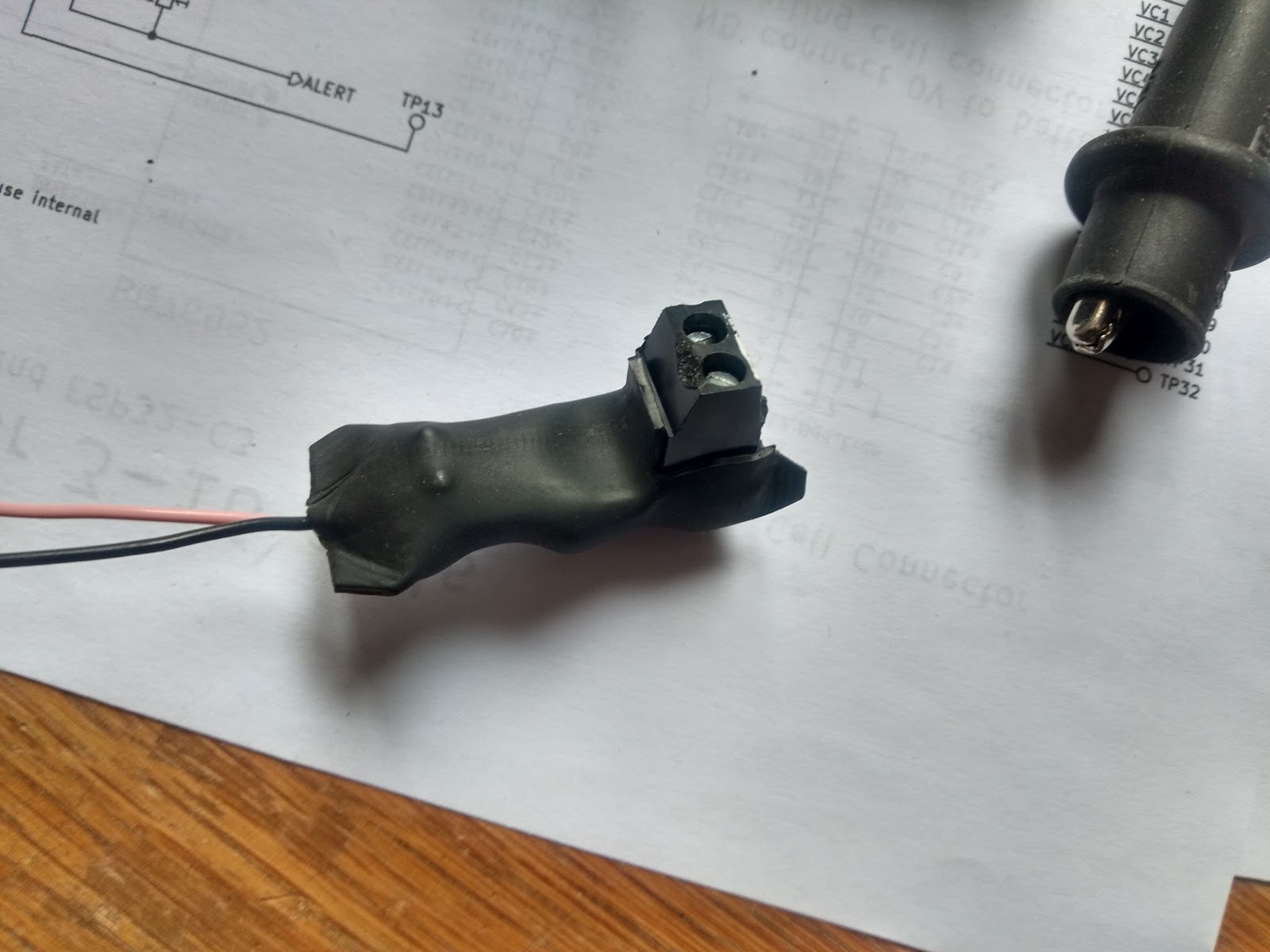

7/3 tile, lino prep, sockets, DB wired to main.

8/3 lino, cupboards, threshold strips, skirting behind base units

9 cut hole for tap, reinforce sink, fit sink and base. Plumb sinks.

35 days.

10-

11 6h. fit towel rail and temp 120cm wooden. remove cooker. test fit new worktops

12 fitted worktops. Colorfil and wood glue one side, well clear of each other. No space for biscuits. Scraped back and filled joint again. Filled white top of edging strip with limited success.

13 removed socket, moved oven socket, moved ignition socket. Screwed tops down. hobs. Edges sealed with white silicone thattook ages to go off.

14 fit oven and hob sealed with silicone, splash back, glass door, extend gas as it hit oven rear!

15 fit sink edges and sink itself sealed with silicone.

39.5 days

16--

17 tile kitchen. 1 hour. Tiles on floor all loose.

18 grout 1h

19 silicone + caulk. Temp fit utility worktop 3h

20-

21 2h Painted 1 coat linseed both sides of osb floor. Cleared shed base and added hardcore and weed matting

22 pm floor and 1 wall

23 shed south and west walls.

24 shed North Wall and finishing West

25 finish west roof and roof. Sealed ends of cut wood and fitted external angle. Plumbed.

26 pm wiring, make door.

27 fit door, shelves, shift stuff

28/4 - 31/4 -

1/5 fit loo + basin am

10/23 Bought Ikea doors as coated chip has shot up in price. Fitted all cupboard doors.

18/11/23 Finally changed the HW 22mm pipe to ensuite for 15mm in loft last month. Today swapped all the bitty plumbing from cylinder to main connections for 16mm PER. The HW JG pipe was creased on a formed corner.

To-do

caulk house

Oil shed door

Air slot for induction hob

Seal bathroom sink